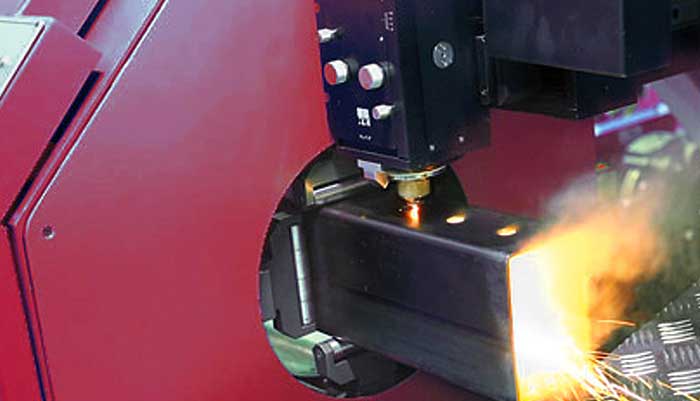

Tube Laser Cutting Systems Jewellery

Get exactly the right solution to your specific laser fabrication needs while delivering process quality and efficiency to metal and non-metal fabricating.

Motion Dynamics is a major manufacturer of neurological sub-assemblies. They include steerable catheters as well as "pull wire" assemblies. Our StarCut Tube machines are used to precision cut key components.